BONETTO AUTOMATION’s

Our pre-engineered laser welding cells offer a high degree

of flexibility to end customers with the ability to handle different

configurations for feeding, welding, assembly and testing.

LASER WELDING BENEFITS

Welding lasers create a highly concentrated heat source, capable of creating keyholes with lower distortion in the welding zone and a smaller volume of weld metal.

The reduced width of the heat-affected zones on both sides of the weld minimizes the thermal damage and loss of properties in the material. This is the best available solution for high-precision welding.

Laser welding allows considerable savings in consumption of consumables due to the minimum of waste and the very high precision guaranteed.

If the application requires the highest level of aesthetic quality, laser welding is the best choice. Laser welding guarantees high mechanical strength of the sealed joints combined with low part deformation and extreme precision of the welding line. It ensures a thin and smooth result, even on very light materials.

Automated laser welding offers consistent and guaranteed quality through the high repeatability ensured by the robotic systems used.

OUR MACHINES

Custom Fixtures

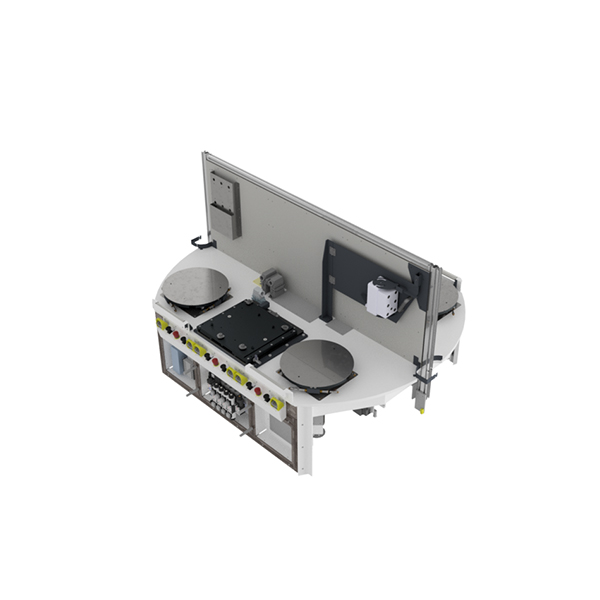

Laser-Flex 1000

- Solutions: fixed optic | 6axis industrial robot

- Laser source: All the laser sources (depending on the project)

- Dimensions: 2415 x 2800 x 3000 mm

- Weldable pieces: Medium to large

- Production rate: Suitable for flexible production with the possibility of manual loading and rapid retooling

- Configuration: Robotic 3D welding

- Welding optics: e.g. SCANSONIC | OPI Photonics

- Materials: Steel | stainless steel | alloyed steel | unalloyed steel | copper | plastic

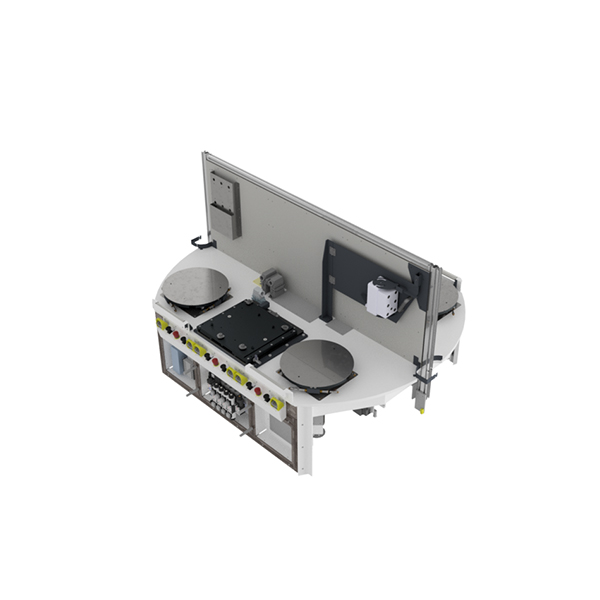

Laser-Fix 200

- Solutions: fixed optic | 6axis industrial robot

- Laser source: All the laser sources (depending on the project)

- Dimensions: 2300 x 2400 x 2500 mm

- Weldable pieces: Small to medium

- Production rate: Suitable for high production rates in fully automatic cycle

- Configuration: 3D welding fixed optic

- Welding optics: e.g. SCANSONIC | OPI Photonics

- Materials: Steel | stainless steel | alloyed steel | unalloyed steel | copper | plastic

Laser Smart 50

- Solutions: fixed optic | 6 axis industrial robot | XY electrical axis

- Laser source: All the laser sources, depending on the project

- Dimensions: 1400x1220x2200 mm

- Weldable pieces: Small to medium

- Production rate: Suitable for proto components in robot configuration or high production rate with fixed optic

- Configuration: Fixed optic or robotic 3D welding

- Welding optics: e.g. SCANSONIC | OPI Photonics

- Materials: Steel | stainless steel | alloyed steel | unalloyed steel | copper | plastic

MAIN PRODUCTION SECTORS:

FEEDING SYSTEM ACCESSORIES

Expertise

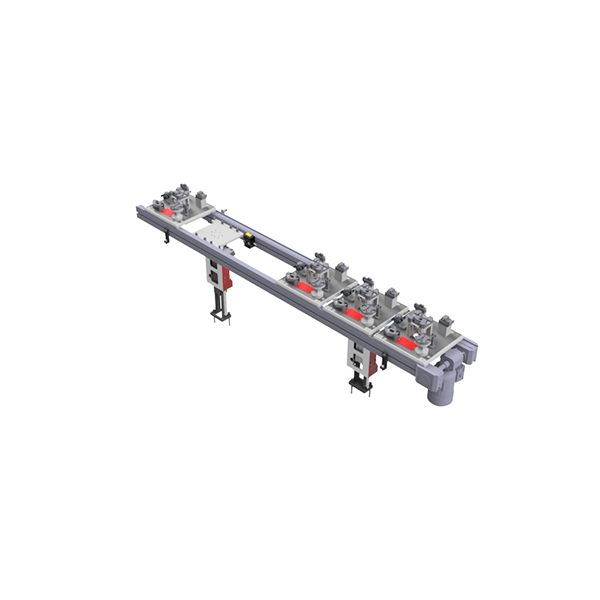

Pallet conveyor system

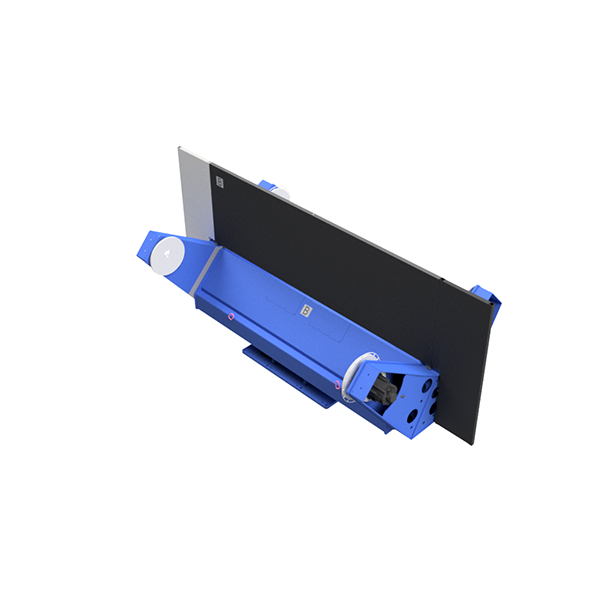

Positioner

Drawer

CERTIFICATIONS

ISO 9001:2005 is a standard that contains several guidelines of the ISO International Organization for Training relevant to the quality of small and medium enterprises. We can compare ISO 9001:2005 certification to a sort of “license” that certifies the quality of a company: the quality of a company becomes certifiable.

The quality certification, in addition to helping the company in the management and simplification of internal processes, thus creating a reference point that streamlines procedures and methods, allows to really demonstrate to consumers the quality of products and services.

Ai sensi dell’art. 1, comma 125-quinquies, della Legge 4 agosto 2017, n. 124, si dichiara l’esistenza di aiuti oggetto di obbligo di pubblicazione nell’ambito del Registro nazionale degli aiuti di Stato.